We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

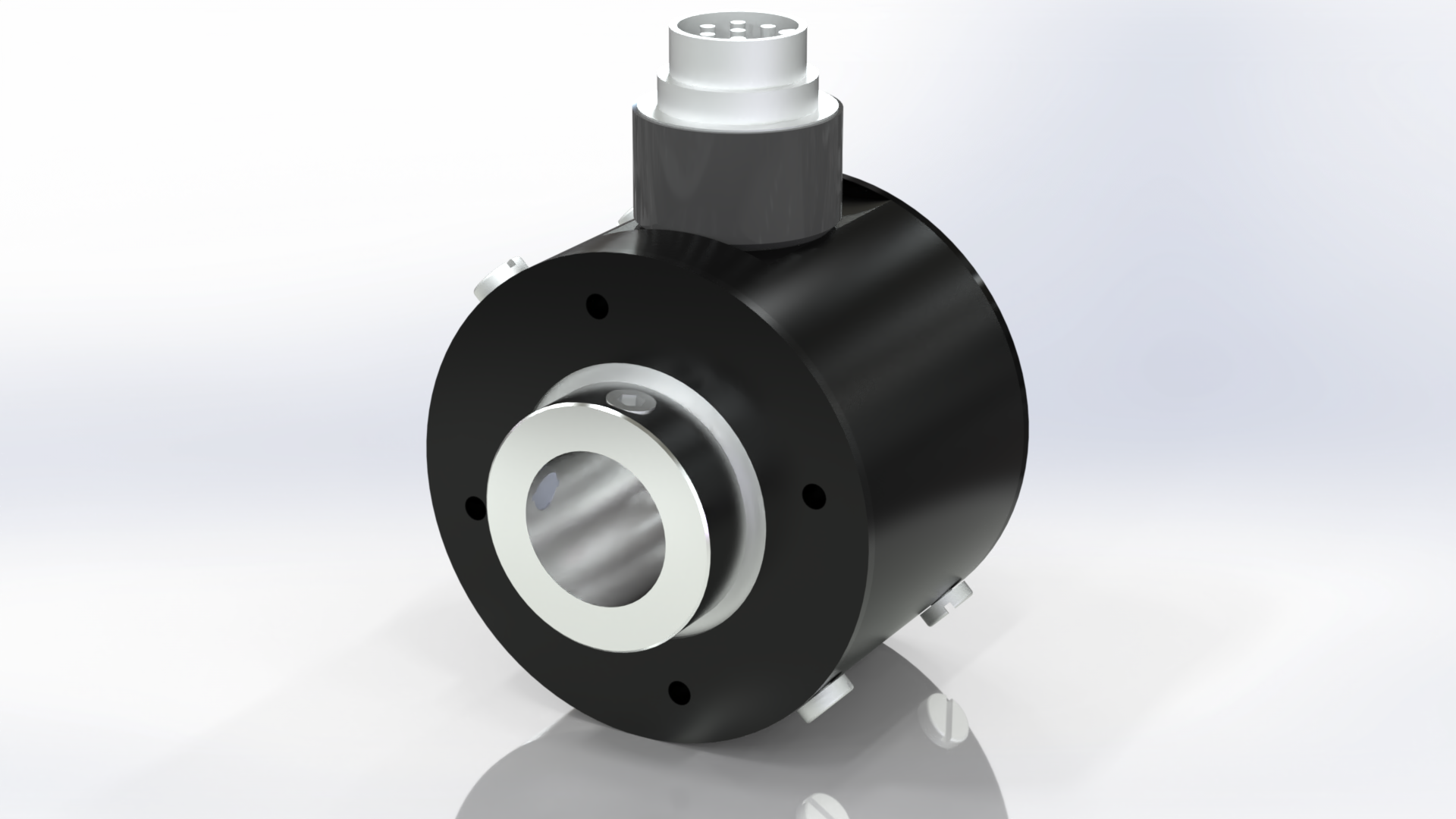

Hollow Shaft

Ideal for space-constrained installations

Hollow shaft encoders are designed with either a through-bore or blind-bored shaft which mounts to a rotating shaft. They "float" on the shaft eliminating the need for a shaft-to-shaft coupling and mounting adapter saving space and cost. A tether or flexible mounting bracket prevents the encoder from turning and absorbs shaft-to-shaft misalignment increasing bearing life.

Shaft Encoders Specifications

| Model | Housing | Shaft Size | Features |

|---|---|---|---|

| R20 | 2.0" Cube | 1/4", 3/8" | Standard shaft encoder with precision bearings |

| RBL | 2.0" Cube | 1/4", 3/8" | Light-duty shaft encoder |

| RL | 3.0" Diameter | 3/8" | Heavy-duty rotary encoder |

| RL-P | 3.0" Diameter | 3/8" | Heavy-duty rotary encoder with pigtail connector |

| RBS | 2.0" Cube | 1/4", 3/8" | Enhanced features for precision applications |

| RS | 2.25" Cube | 1/4", 3/8" | Standard cube-style encoder |

| RS-P | 2.25" Cube | 1/4", 3/8" | Cube-style encoder with pigtail connector |

| RBX | 2.0" Cube | 1/4", 3/8" | Extended temperature range |

Hollow shaft encoders are designed with either a through-bore or blind-bored shaft which mounts to a rotating shaft. They "float" on the shaft eliminating the need for a shaft-to-shaft coupling and mounting adapter saving space and cost. A tether or flexible mounting bracket prevents the encoder from turning and absorbs shaft-to-shaft misalignment increasing bearing life. Select from a wide offering of body sizes and styles. Once you have decided on a style you can configure your encoder to your needs using our configuration center.