We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

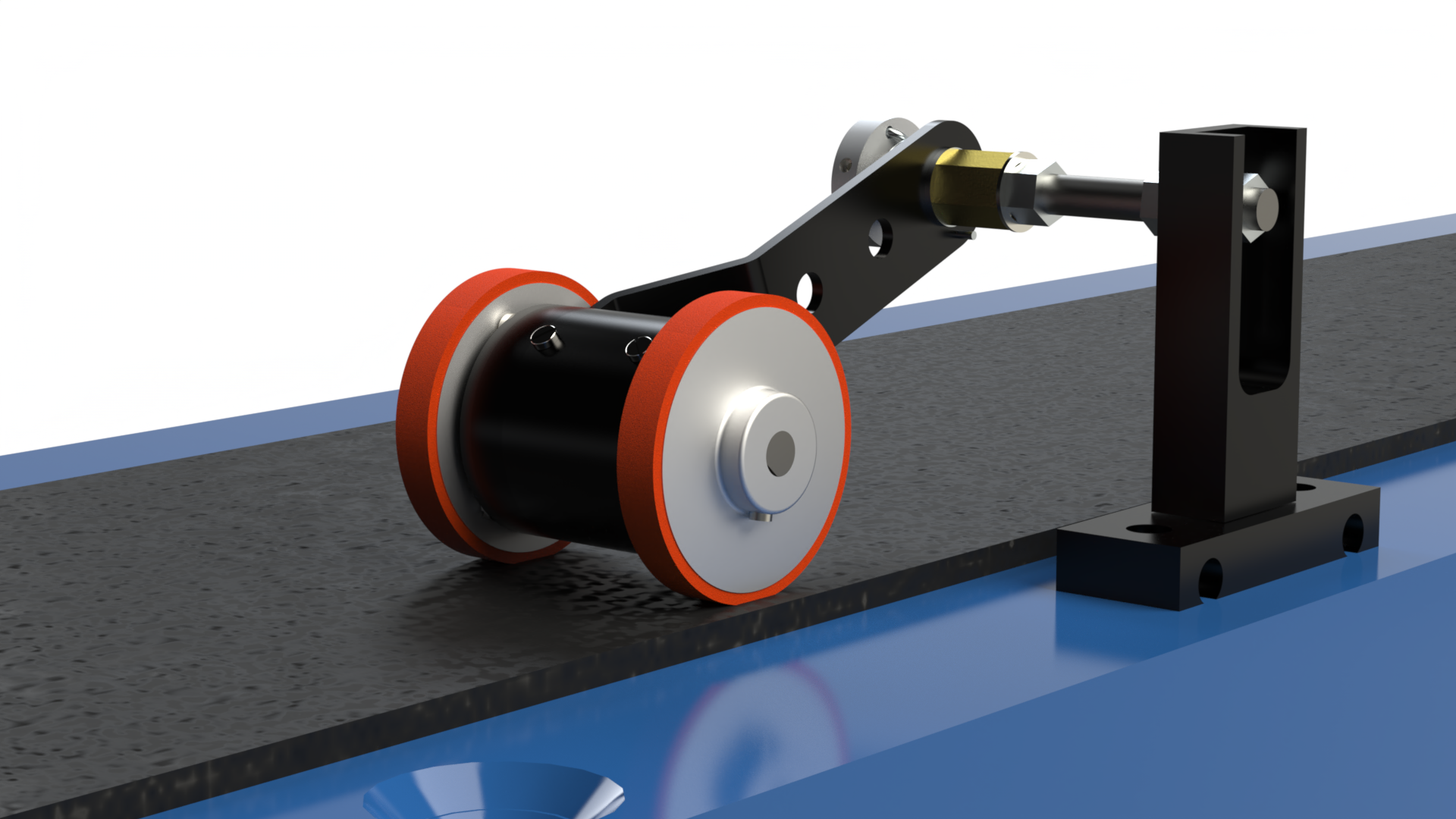

Wheel

Ideal for conveyor systems, printing, and inspection tasks.

Wheels are precision ground with exacting tolerances, versus a roller which has a much larger tolerance and its circumference seldom translates into an integral number of encoder pulses per unit of linear movement

Ensure accuracy in material handling and movement tracking systems.

Our single and dual wheel encoders offer additional advantages:

- Integrated mounting arm for easy installation

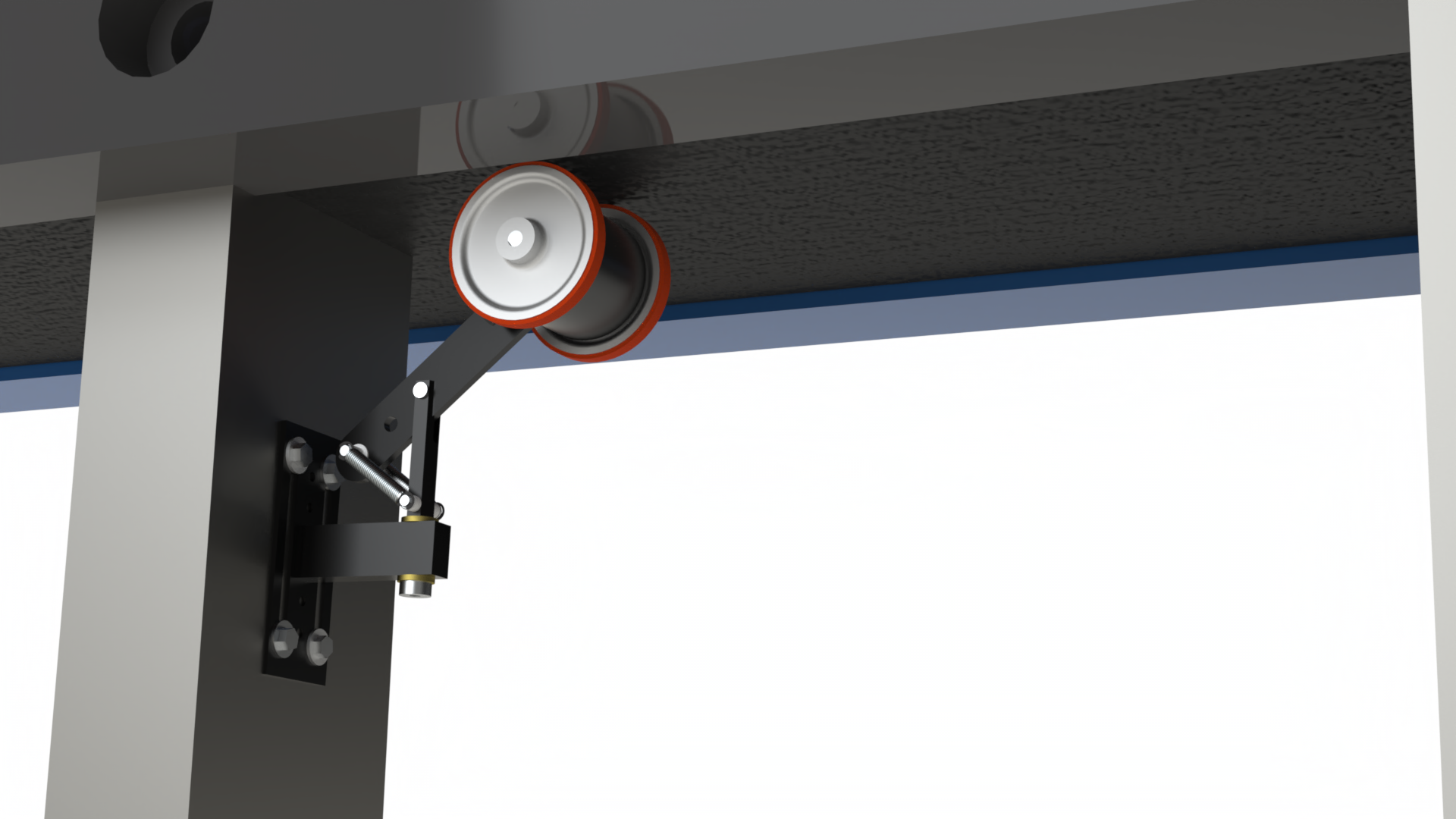

- Accessories for mounting above or below a conveyor or moving web

- Rugged construction for continuous duty in industrial applications

- "Anti-Jitter" feature eliminated measuring and tracking problems and the resulting miss-sorts often encountered when a conveyor or web stop or restarts

- Circuit protection that eliminates failure caused by the significant levels of static electricity often associated with conveyors

- "Programmable" versions that enables selection of various features at installation time, such as the pulses per revolution and the output circuit type, resulting in maximum flexibility with minimum inventory

Wheel Encoder Specifications

| Model | Output | Max RPM | Resolution (PPR) | Shaft Size | Housing Material | Temperature Range |

|---|---|---|---|---|---|---|

| RH | Incremental | 6,000 | 1 to 10,000 | 1/4" to 1/2" | Aluminum | -20°C to 85°C |

| RH-P | Incremental | 6,000 | 1 to 10,000 | 1/4" to 1/2" | Aluminum | -20°C to 85°C |

| RHX | Incremental | 6,000 | 1 to 10,000 | 1/4" to 1/2" | Aluminum | -40°C to 85°C |

| RW | Incremental | 6,000 | 1 to 10,000 | 1/4" to 1/2" | Aluminum | -20°C to 85°C |

Wheel encoders ride directly on the moving material, use a wheel tread having a high coefficient of friction, and have a very low starting torque resulting in virtually no slippage of the wheels on the belt. In addition, the wheels are precision ground with exacting tolerances, versus a roller which has a much larger tolerance and its circumference seldom translates into an integral number of encoder pulses per unit of linear movement.

Our single and dual wheel encoders offer additional advantages:

- Integrated mounting arm for easy installation

- Accessories for mounting above or below a conveyor or moving web

- Rugged construction for continuous duty in industrial applications

- "Anti-Jitter" feature eliminated measuring and tracking problems and the resulting miss-sorts often encountered when a conveyor or web stop or restarts

- Circuit protection that eliminates failure caused by the significant levels of static electricity often associated with conveyors

- "Programmable" versions that enables selection of various features at installation time, such as the pulses per revolution and the output circuit type, resulting in maximum flexibility with minimum inventory

Select the body size and wheel configuration. You can then configure your encoder to your needs using our configuration center.